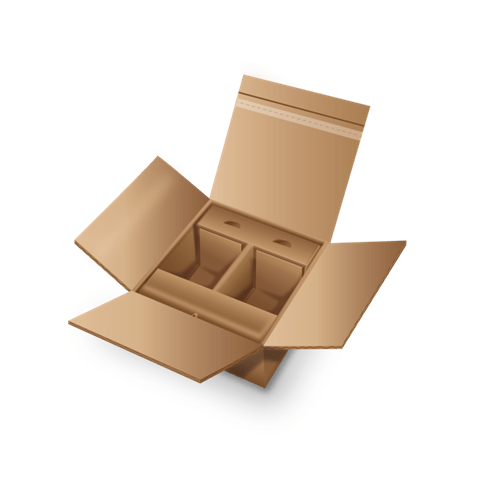

If the company needs to ship anything, there’s a chance that you’ve thought about the possibility of investing in some protective packaging. Bubble wrap, foam, and other types of packaging protection will help prevent the items from becoming damaged.

While businesses look for different opportunities, this is an area that’s much safer than sorry. If you’ve ever had a package arrive with damage, you’ll want to re-think how the business and the packaging protects this, or else you will risk losing the profit margins and refunds.

Why it’s important

It’s important because usually 10% of packages do arrive at their destination with some form of damage. While this does vary, it can definitely be a greater number depending upon the type of service you use. For instance, FedEx does have packages that arrive 7% of the time, whereas 11% for UPS packages.

You don’t want to take a chance with this type of thing. As a business, you should use protective packaging.

There are a few instances to us ethic, and they’re listed below:

You Sell Objects that are Fragile

When you’re shipping breakable products, protective packaging is the answer. Wrapping items that are breakable in foam or even bubble wrap does protect them during the transit process.

Even if the products aren’t breakable, or made of glass, you’ll want to make sure that you have packaging that’ll hold up against the bumps, shakes, droppings, and other types of damage that happens.

While it’s totally impossible to fully guarantee that everything will arrive intact, you’ll improve this through package upgrading.

Even if there are slight doubts on the products and their ability to arrive in an intact manner, always err on the side of being protective with the packaging.

You’re Shipping to Different Countries

With international mail, it gets tossed around a lot more, since it’s got a far longer journey. That means, in order to save the products and ensure they’re shipped correctly, you need to use protective packaging.

Something that you may not even bat an eye about not protecting will arrive damaged in a lot of instances. This leaves the products within this further exposed to more damage. Protective packaging is not just used to protect items from being moved about, it also offers an extra layer especially if the envelope or the box rips. This is also good if the person that’s delivering straight up leaves this outside, since the factors change when you do have a larger distance.

The items are Easily Scratched

If you’ve had a product that’s easy to scratch or scuffle when you ship it, especially when improperly manhandled, you’ll want to use protective packaging. Customers don’t want this, and this can provide a barrier around it. it shields the items from further scratches by the inner parts of the container when you ship them.

You’ve Experienced some form of Damage Before

Even items that are durable do become damaged when shipped. Some surfaces are scratched, cracked, dented, and the like, especially when jostled. So no matter what is sold, you’ll want to add some protective packaging for item shipping.

This is especially the case if customers complain about their items being damaged in the mail. No matter how good the product is, your review will be bad if that does arrive damage.

It’s very important to package out the items with some care, in order to ensure that there is some client satisfaction.

Consider this when you’re making sure that you get the right protective packaging for your needs, and the needs of the customers as well too.