Having packaging that’s got the instructions inside is great. Some people like to have the item and instruction right there to look at.

But there is one problem with such. It can cost money and resources to print the paper instructions as a separate addition. Some have started to use the QR codes, but it only works so much, and it can be ineffective for packaging that needs to be changed.

With that said, here’s a few different ways to ensure that your packaging has the items. One of the best ways is to print it literally on the box. This is designed as a visual instruction means for assembly. While it might not seem like much right now, there’s a ton of amazing benefits that come with this, to the point where more and more people are considering this, especially in the assembly process.

How it Works

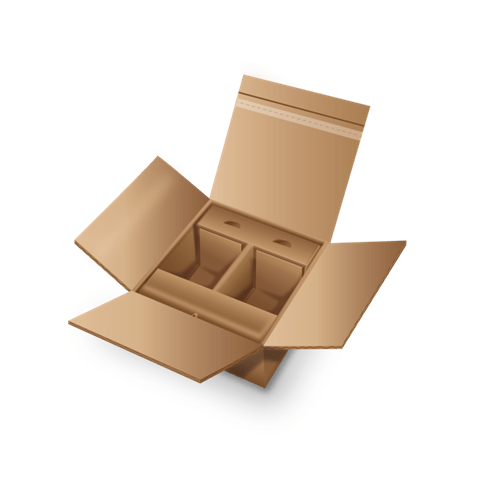

Sometimes, you can add the diagrams to the lid of the box, and then customers can look at it as they put the item together.

Perforated sections that a customer can tear out might also be used. This aligns directly with the components of the product.

If it’s small enough, it can fit on the box. Some people like to include it right under the thank-you note on the boxes, so not only are you acknowledging the support of the brand you have, you’re also able to give them something that really shines.

The Applications

With this type of packaging, there’s a lot of applications.

Flat-pack furniture, especially those that are looking to optimize the box space, might use this. That way, people aren’t having to fish out the instructions from in the box, sandwiched between parts.

DIY kits are another. People are already learning how to build something themselves. Giving them instructions that are built in is something that they can enjoy, and works well for the overall experience that’s there.

Finally, tech gadgets. This technology is great, since it can help to ensure that the items are used in a manner that is effective and useful for everyone that’s involved. Overall, the packaging is made with some pre-built instructions, and then, you can use it.

The Benefits

There’s a ton of benefits that come with this.

First, simplified assembly. It’s so much easier to assemble these items, to the point where some people prefer it. they don’t have to look at complex instructions in order to get the items that they need.

There’s also fewer instruction manuals. Think about all of the resources that you’ve saved just through doing this. overall, it optimizes space, printing, costs, and also makes you look more sustainable compared to others as well.

The future of this Packaging

Obviously getting the item to be printed on the packaging is a challenge. Some companies are working with this right now.

However, there are new ways, including 3D printed packaging that can unfold into the product’s components. Then, a customer can just take each component based on the printed design and then transfer it to the actual item. It creates better visuals for those to work with. Some have even made it in a manner where it unfolds exactly into the item that’s there, making it even easier for you to enjoy.

Yes, built-in instructions work wonders for your packaging, and giving customers a means to enjoy these built-in instructions is the best course of action, and also helps to make it so that you’re able to really improve the packaging, making it worthwhile for everyone who buys from you as well.