Privacy matters. Especially in packaging. Certain product categories need this, both to protect your customers and also to prevent theft.

Health and wellness supplements, with the right protection, offer a better, safer packaging experience. Personal care items, especially when it involves a customer’s name and health information, is another one. You definitely want to keep this discreet. The telehealth world also needs to use this, especially since they’re now dealing with sensitive categories.

Finally, some need this protection because it requires them to be protective of these items. Collectibles and luxury items need protection, especially when getting to the customer, if only to prevent theft as well.

The Best Supplies for Preventing This

You want supplies that are not branded for starters, that won’t give you away.

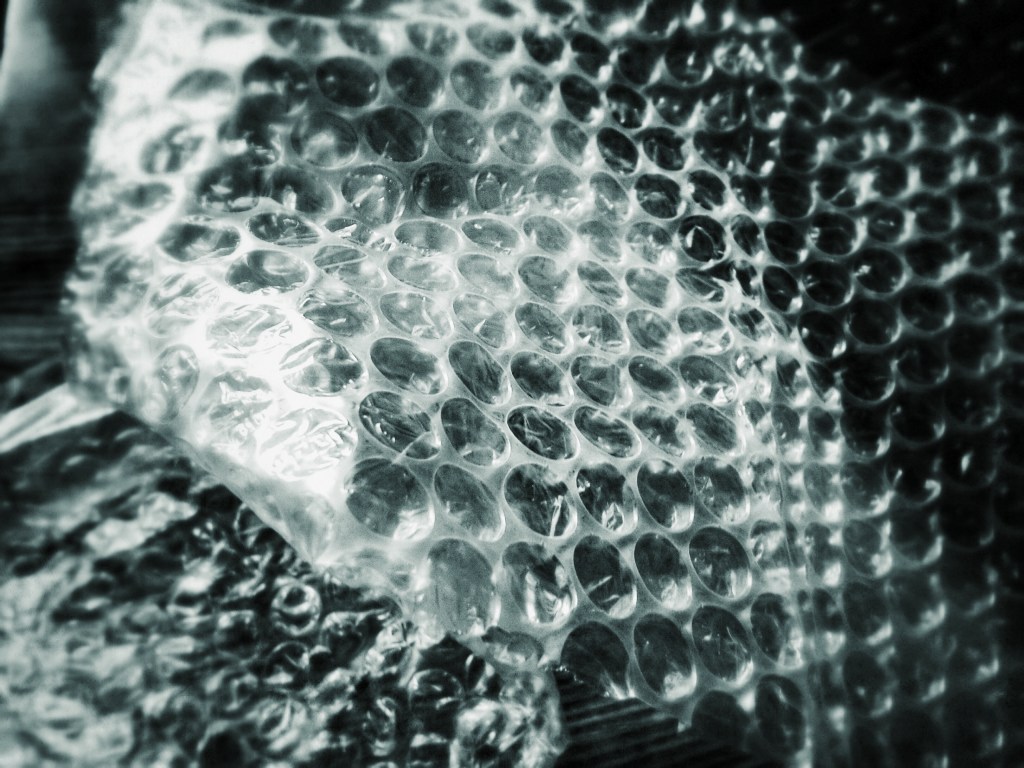

You also want them to be strong too, as strong items will offer better protection.

Finally, you want these to be tamper-evident, as this will offer you more protection from such scenarios.

No-logo mailers are one example of this. not having the logo will not give people any sort of possibility that it’s you. blacked out tape also will hide just what this is, rather than the transparent tape that will show what’s inside.

Finally, the type of box that you use is good too. rather than using a bunch of tape or anything that will give it away, a fold-to-lock mailbox will help with keeping things locked until you’re ready, offering some next-level discretion when shipping out items.

How to Balance Branding with Customer Discretion

The problem with this type of packaging is that some of these may involve issues with brand recognition and customer discretion that will be a problem for some.

You want to give subtle indicators, either inside or on the box. So how do you prevent oversharing? Well, you can add various brand colors, or a pattern that isn’t the logo. It will be noticeable to the customer, but to the other people who see this, it won’t work.

Another example is using a simple box on top, but then the contents are branded. Lots of companies that ship sensitive items use this, where the customer will know when they open it but keeps thieves from getting into this.

Improving Customer Support Through This

Now, you want to make sure that the boxes are discreet, especially with health products. Don’t even give the name of your company, as this will help with reducing the customer embarrassment people have. With sensitive health scenarios, having your information plastered all over the box is not the way to go, so having this kept discreet is a bib part of this.

In turn, when you give customers this, it promotes loyalty too, a big part of customer awareness, betterment, and approval. Customers feel like they can trust you, and in turn, it will help to improve sales and customers returning to your packaging.

All of this comes together to offer next-level discreet shipping without compromising the functionality of such items. Doing so will help to improve your packaging, and will in turn, make customers feel better about trusting you.

Being able to make your packaging not only stand out but also look discreet when in transit is a big part of shipping. In doing so, you’ll be able to improve the overall repute of your packaging, and make it really shine. Start to focus on your discreet packaging today, and see for yourself just how powerful shipping without blabbing is, and how, in turn, will make customers feel better when buying from your brand and engaging in return purchases.